Nowadays, with a lot of industrial diesel engines and many marine diesel engines RS Motor is a competitive firm with hired maintenance contracts. This allows our company to be competitive in both National and International Market, as well as being synonymous of guarantee.

RS Motor is specialist on performing different kind of works related to the Overhaul or the repair of industrial diesel engines

Any type of engines of the main brands that RS Motor make Service and regardless of where they are located, RS Motor is able to provide an efficient, fast and quality solution. Many years of experience mean that our specialized technicians and engineers can perform any type of Overhaul either at RS Motor’s facilities or “on-site”.

What type of repairs or Overhauls do we perform on diesel engines in RS Motor?

In short, we give you a global idea of the most common repairs of engine parts that we usually carry out in our facilities.

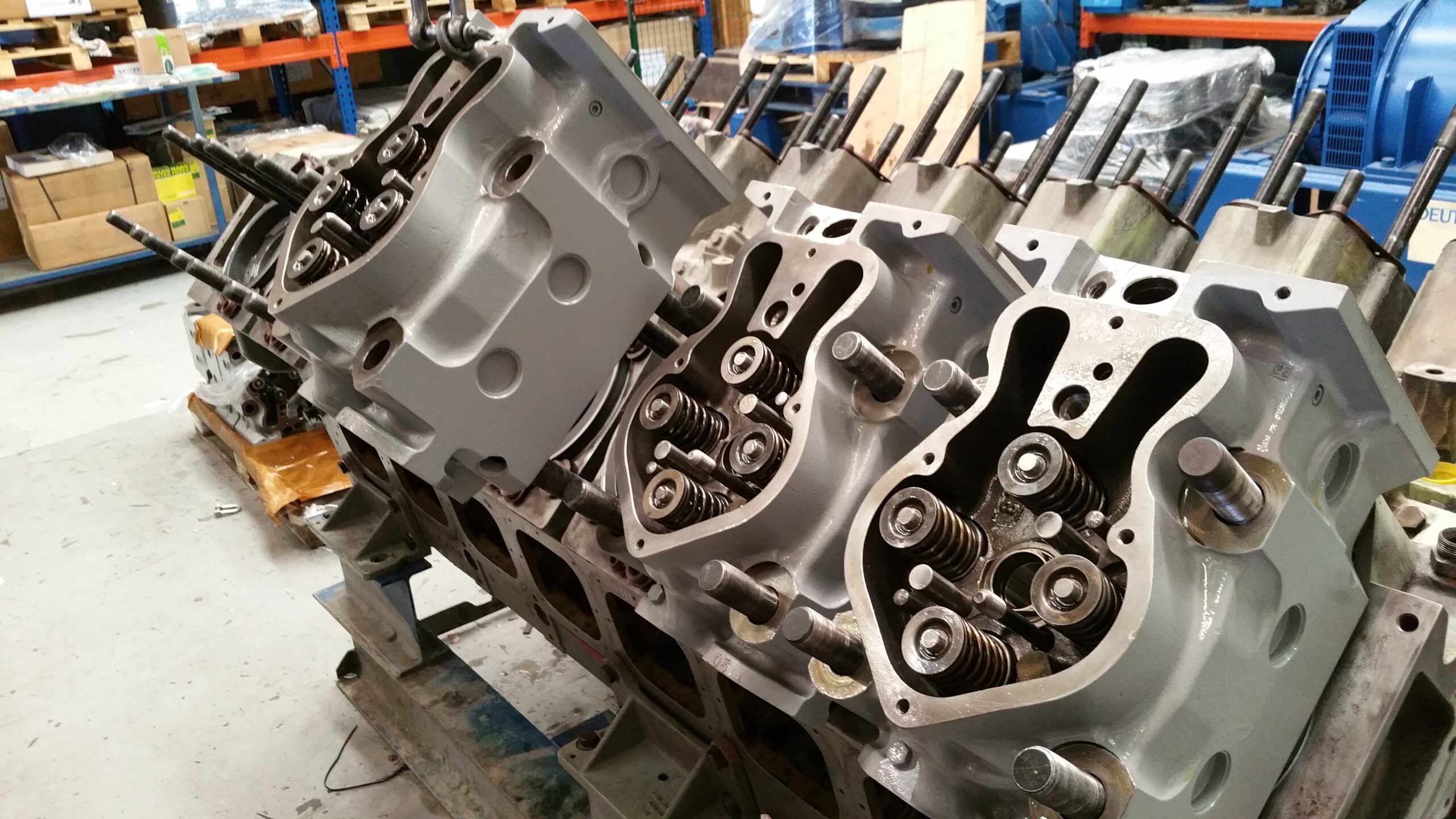

- Reconditioning of cylinder heads: Renew of valves, seats, valve guides, sleeves (depending on the model of the cylinder head), O-rings, machining and/or repair of the cylinder head’s core (when necessary), machining of the cylinder head faces, complete assembly and final hydraulic test.

- Reconditioning of connecting rods: Verification of the parallelism of the connecting rod body. If it accomplishes the standard tolerances, we renew the small end bushing and the studs or bolts.

- Verification of starters: Thanks to the specialized electrical workshop of RS Motor, where there are specific equipment to check if the starters are in good condition or not, RS Motor can repair electrical or air compressed starters.

- Ultrasonic cleaning of intercoolers: Dismantling of the charge air cooler, ultrasonic cleaning by using an ultrasonic cleaning machine, mechanical cleaning of intercooler’s body and covers, renew of sealing gaskets, assembly and final hydraulic test.

- Verification of the crankshaft dimensions: RS Motor has special tools and equipment which allows to verify the dimensions of the crankshaft.

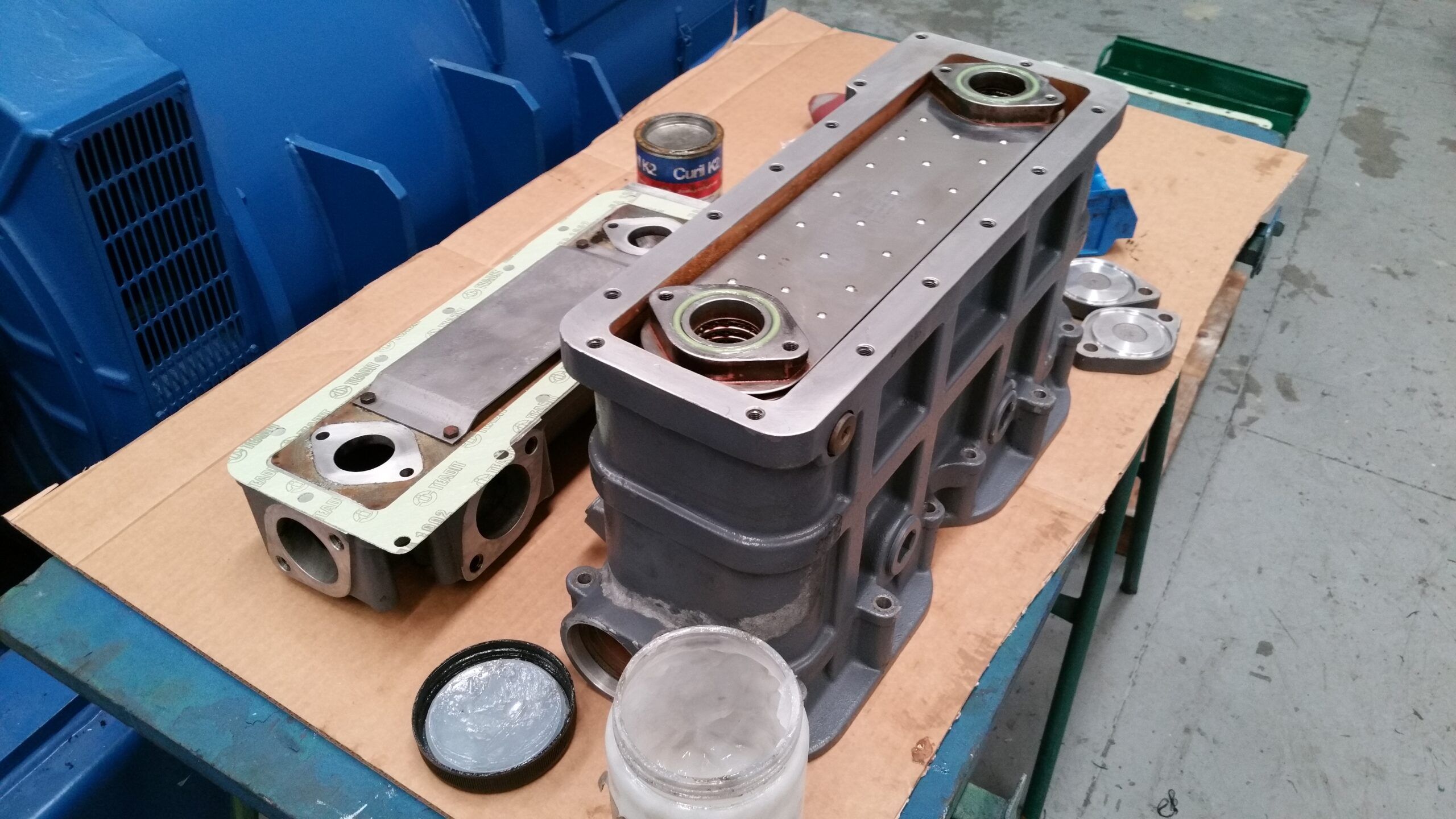

- Reconditioning of oil cooler: Disassembly, renew of sealing elements, final assembly and hydraulic test.

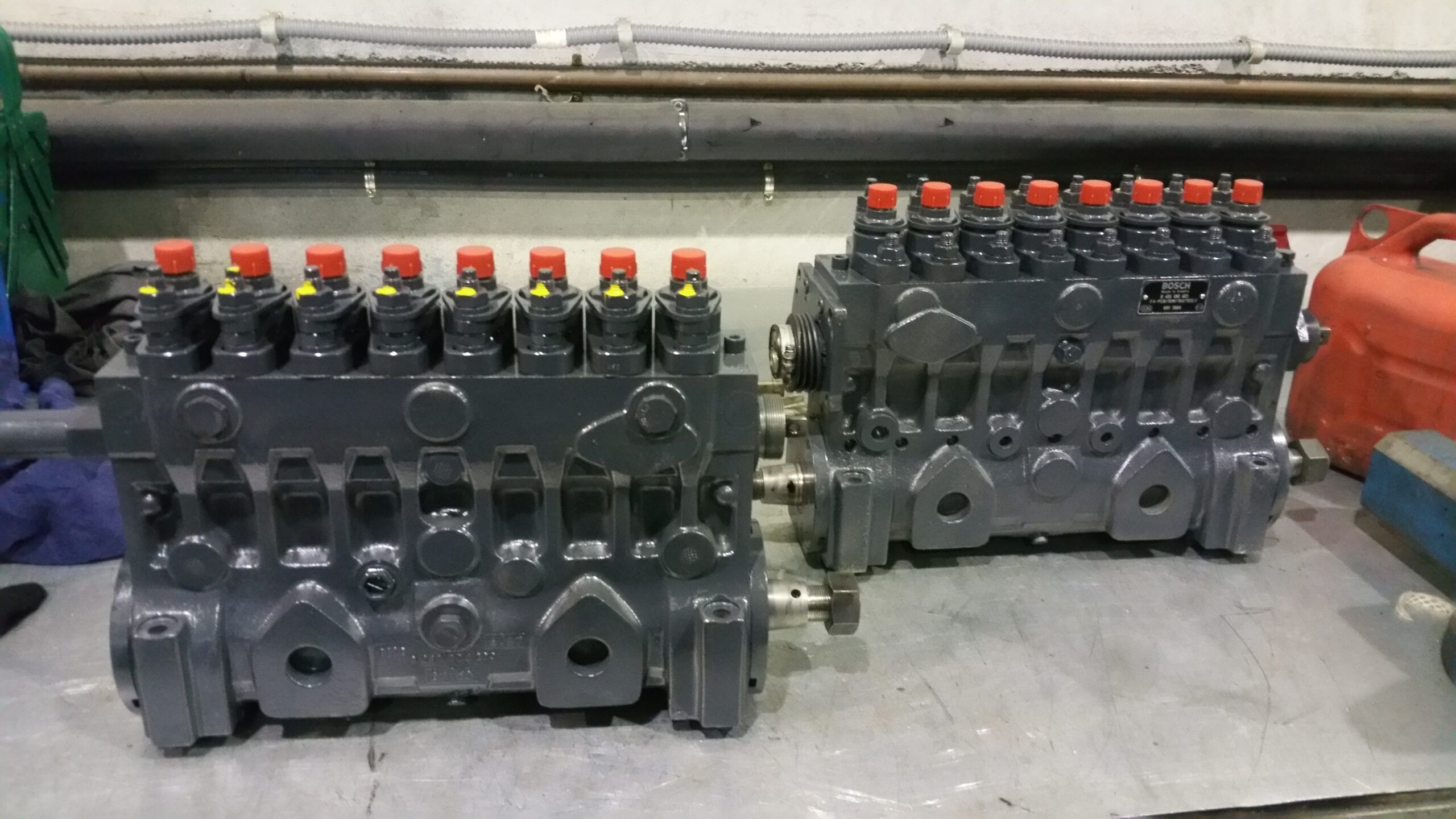

- Refurbishment of fuel pumps, oil pumps and/or water pumps: Renew all o-rings, gaskets, watertight gaskets, pinions (if possible), bushings and so one.

- Machining or repair of the engine block: When it is necessary to perform some works, such as machining the upper and/or lower parts of the engine block.

- Renew the main engine parts: Main bearings, pistons, connecting rod bearings, cylinder head gasket sets, cylinder liners, axial bearings, camshaft bushings …

- Renew other engine spare parts: Gaskets, screws, bolts, nuts, o-rings, rubber springs, nozzles, injectors, oil filters, air filters, fuel filters…

Maintenance on diesel engines

There are many types of maintenances that can be carried out on marine diesel engines or industrial diesel engines. Thus, RS Motor is specialist in the following ones:

- Corrective maintenances: This kind of maintenance should be performed as soon as possible in the event of an unscheduled engine stop due to various causes (seizures, high temperatures, high pressures, electronic failures …). The works are adapted to the needs of the engine at that time.

- Preventive maintenances: Type of maintenances carried out taking into account the running hours of the engine. The interval varies from one engine manufacturer to others. Usual names are minor preventive maintenance and major preventive maintenance (also known as engine Overhaul). All tasks which need to be performed in this kind of maintenance of engines is listed in the manufacturer’s maintenance plan.

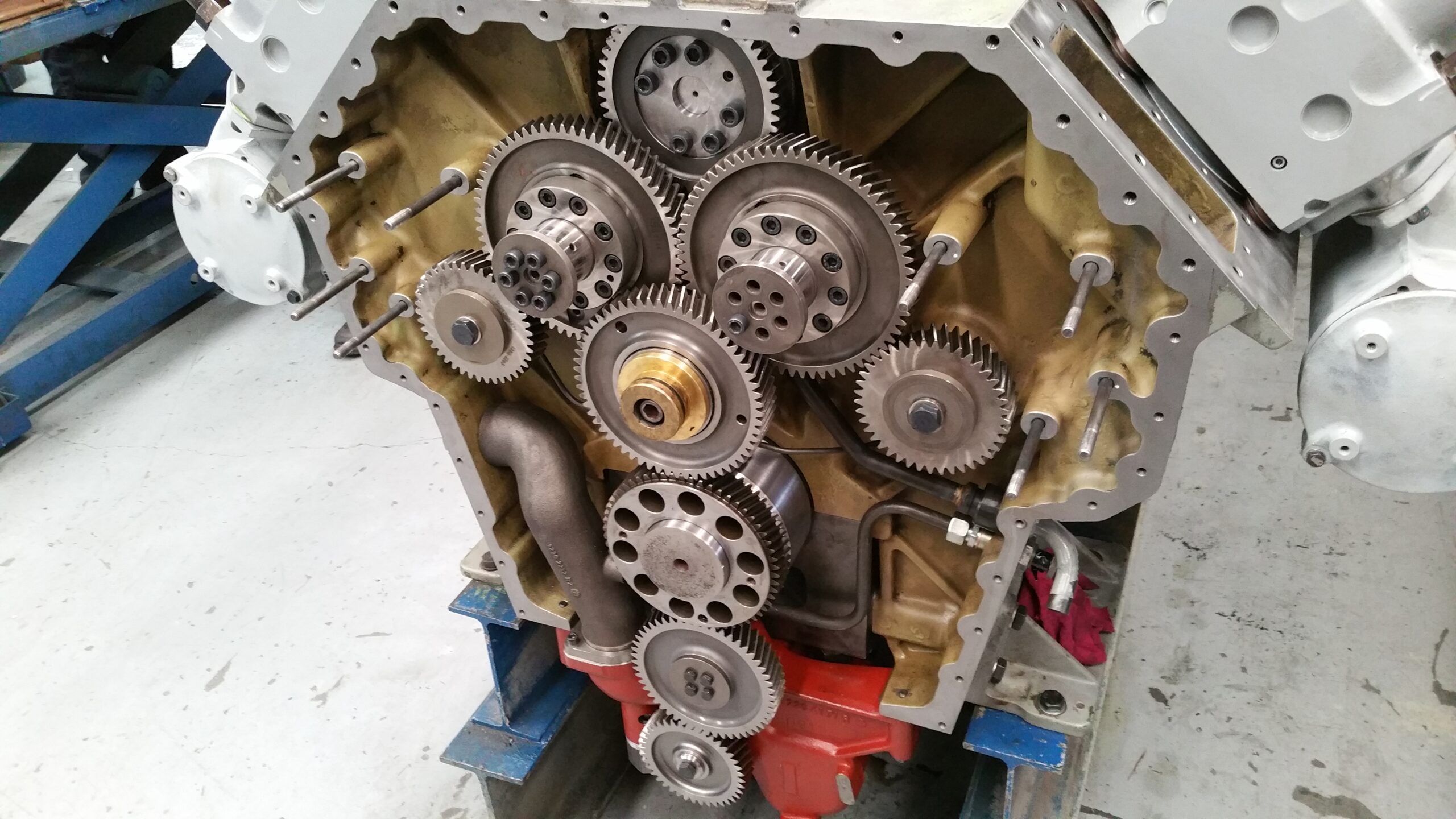

In this occasion we show how RS Motor repairs an industrial diesel engine, which generates about 1,7 MW – 1,8 MW of electrical power

An important work is to check the crankshaft dimensions. If it is within tolerances, we start to renew the main bearings, we also reconditioning the connecting rods in RS Motor and so one.

In some occasions, we to make some extra works like machining the bottom part and the upper part of the engine block. The same happens if the core or the faces of the cylinder heads are not in good status. Apart from the renew of valves, seats, valve guides, springs… sometimes the core of the cylinder head can be damaged. To solve that, RS Motor machines them (if possible) in order to leave them able to be used again.

Other parts that we have to reconditioning and verify are: intercoolers (charge air coolers), oil coolers, pumps… When these elements are reconditioned, they are submitted to a final hydraulic test to verify the absence of leaks.

Once all works are finished, RS Motor assembles again the engine for sending it to the Power Plant or to the vessel again.

To sum up, an efficient Technical Service linked to the high quality of the spare parts, allow the engine able to run on a more regular basis.

Service on diesel engines

RS Motor is specialized on carrying out several works on the diesel engines listed below:

|

DEUTZ |

|

TBD616V8 TBD616V12 TBD616V16 TBD620V12 TBD620V16 TBD645L6 TBD645L8 TBD645L9 TCD2016V8 TCD2016V12 TCD2016V16 TBD640 SVB628 ….. y muchos más |

Overhaul of diesel engines

In many occasions and in plants/ vessels where downtime makes it unfeasible, RS Motor can carry out the Overhaul works using an exchange “shortblock” or an exchange “longblock”, thus minimizing the Power Plant/ vessel downtime due to preventive/corrective maintenance of the engine.